PUF & PIR -TR Panels

For Roofing & Cladding Applications

LLOYD TR PANEL

LLOYD TR PANEL is also made available with 80 microns thick aluminium foil facing as the bottom sheet and known as LLOYD TR ECO Panel with 50 mm thick Polyurethane Foam as core insulation.

LLOYD TR PANEL

LLOYD TR PANEL is also made available with 80 microns thick aluminium foil facing as the bottom sheet and known as LLOYD TR ECO Panel with 50 mm thick Polyurethane Foam as core insulation.

Applications

Data

Fixing

Projects

Properties

For Roofing & Cladding Applications

LLOYD TR PANEL is also made available with 80 microns thick aluminium foil facing as the bottom sheet and known as LLOYD TR ECO Panel with 50 mm thick Polyurethane Foam as core insulation.

Specifications Data

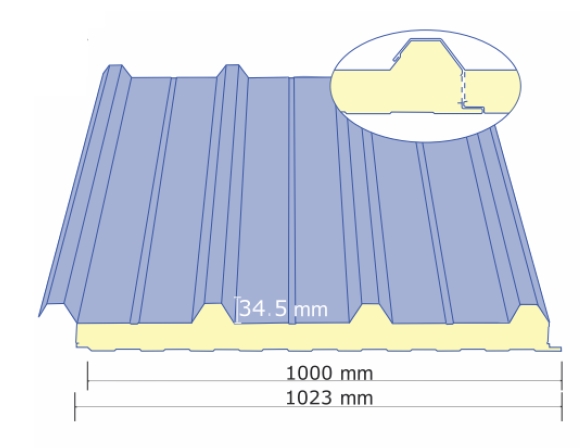

| Top Sheet Profile | LLOYD TR Trapezoidal profiled sheet |

| Bottom Sheet Profile | Plain sheet with slight ribs |

| Panel Thickness | 30mm, 40mm, 50mm,60mm,80mm,100mm, 120mm “Also available 50 mm Lloyd TR ECO Panel with Aluminium Foil facing on one side” |

| Facing Material | 240 MPa Gl with 180 GSM Zn Coating / 300 MPa Galvalume Steel with 150 GSM Alu-Zn Coating |

| Facing Material Thickness | 0.4/0.5/0.6/0.7 mmTCT |

| Facing Material Coating | DFT 20 microns colour coated RMP/SMP/PVDF coating over 5 micron primer. |

Fixing

- Lloyd TR Panel shall be fixed on to the Purlin / Girt with hot dipped galvanized imported self drilling fasteners with EPDM washers and with necessary overlap as per manufacturer's specification.

- Lloyd TR Panel shall be supplied in upto 1 m effective width and in single length upto 12 m without any joints depending on site requirements.

Applied locations

| Properties | Polyurethane Foam | Polyisocyanurate Foam |

|---|---|---|

| INSULATION | CFC & HCFC FREE RIGID POLYURETHANE FOAM (PUF) AS PER IS 12436 STANDARD. | CFC & HCFC FREE RIGID POLYISOCYANURATE (PIR) FOAM |

| Foam Overall Density | 40+/-2 kg/cu.m | 45+/-2 kg/cu.m |

| Foam Thermal Conductivity (K-Value) at 10°C mean Temp. | 0.023 W/m°K - Max. | 0.023 W/m°K - Max. |

| Compressive Strength 10% deformation | 1.25 Kg / sq.cm | 1.25 Kg / sq.cm |

| Tensile Strength | 2.5Kg / sq.cm. - Min | 2.5Kg / sq.cm. - Min. |

| Flextural / Bending Strength | 3.0 Kg / sq.cm. - Min | 3.0 Kg / sq.cm. - Min. |

| Shear Strength | 2.5Kg / sq.cm. | 2.5Kg / sq.cm. - Min. |

| Adhesion Strength (Foam to Steel) | 0.6 Kg / sq.cm. | 0.6 Kg / sq.cm. - Min. |

| Closed Cell Contents | 90 min % | 90 min % |

| Horizontal Burning Characteristics - As per 1S-11239 (Part12) | 125 mm (Extent of Burn) - Max., Fire Retardent (FR), Self extinguishing (SE) Quality Foam. | 25 mm (Extent of Burn) - Max., Fire Retardent (FR), Self extinguishing (SE) Quality Foam. |

| Fire Properties - As per DIN 4102 | B3 | B2 |

| Water absorption (By Volume) | 2% volume at 100%RH. - Max. | 2% volume at 100%RH. - Max. |

| Water Vapour Permeability | 0.24 ng/pasm at 88% RH & 38 deg. C-Max. | 0.24 ng/pasm at 88% RH & 38 deg. C-Max. |

| Dimensional Stability at. | ||

| -25°C cold Temp. | ±2% | ±2% |

| +70°C Hot Temp. | ±2% | ±2% |

Kick start your

project today

We are a one-stop multi-disciplinary solution provider specialising in supplying, contracting and manufacturing of insulation, refractory, pre-insulated sandwich panels, pre-engineered buildings, metallic profiled sheets, fire-proofing and mechanical erection works.