OUR PRODUCTS

LLOYD INSULATIONS (INDIA) LIMITED

An SO 9001:2015, ISO 14001:2015 & ISO 45001:2018 Certified Company

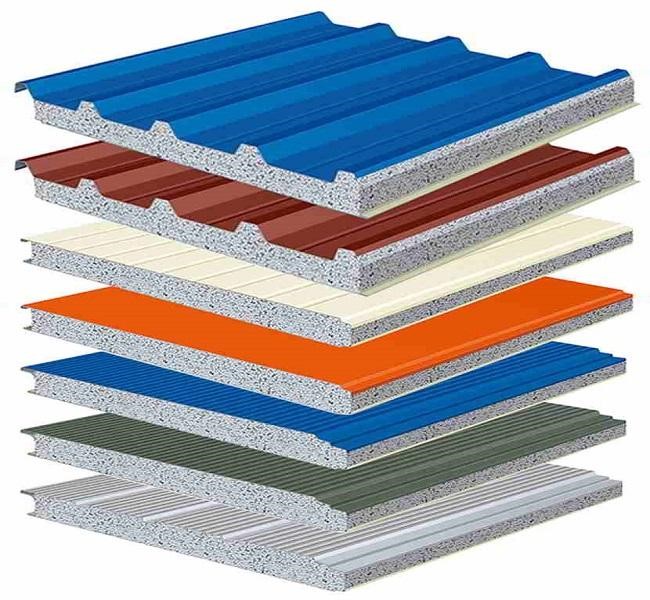

Lloyd Panel System

Lloyd Panel System Offers One Step Solution For Thermal Insulation Of Cold Rooms.

Lloyd panel system comprises of Pre-fabricated sandwich panels with

CFC & HCFC free Polyurethane Foam at a density of 40+2 kg/m3 as core and

with plain ribbed sheeting made out of Galvanized / Galvalume Steel as facings on both sides.

Lloyd PUF Panels come with standard Tongue & Groove joint and optional camlocks. Lloyd PUF Panels are manufactured in the most Modern Continuous & Semi automatic Panel making line and can be supplied in lengths up to 12m (Limited due to restriction in transportation). Lloyd PUF panels are available in a standard width of Tm and in various thickness to suit the industry requirements. The standard thicknesses are 60, 80, 100, 120, 150 & 200mm.

Lloyd PIR panels system comprises of Pre-fabricated sandwich panels with CFC &HCFC free Polyisocyanurate Foam ata density of 45+2 kg/m3 as core and with plain ribbed sheeting made out of Galvanized/ Galvalume Steel as facings on both sides.

PIONEERS IN PRE-FABRICATED PRE-INSULATED PANELS

Being pioneers and leaders in the field of Thermal Insulation, Lloyd Insulations were the first to introduce Pre-Fabricated Pre-Insulated Sandwich Panels in India for Insulated buildings and Modern cold stores and have been serving the Insulation requirements of special buildings and Modern Cold store for the past 25 years.

Lloyd Insulations possesses the necessary Infrastructure, Technical and Financial capabilities to execute turnkey orders with Pre-fabricated Pre-Insulated Sandwich panels of any magnitude.

LLOYD POLYURETHANE / POLY ISOCYANURATE FOAM PANELS

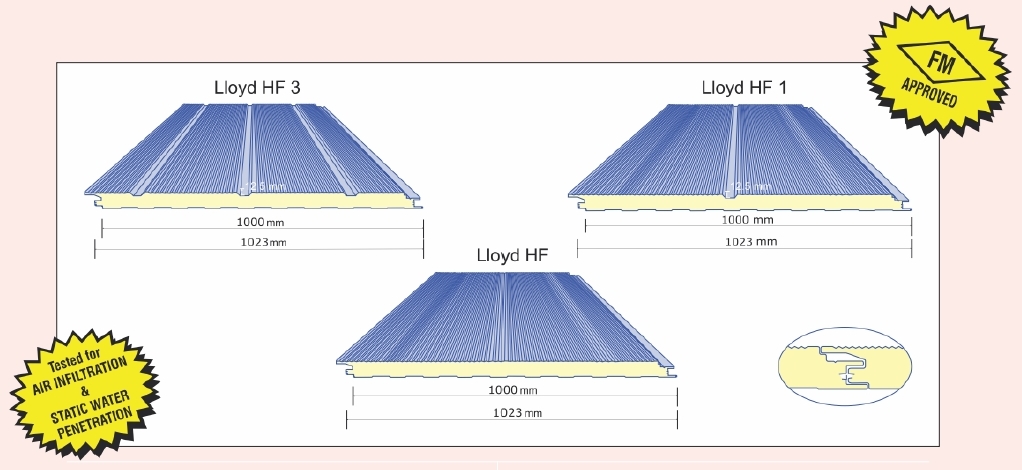

Lloyd PUF / PIR Panel System offers one step solution for Thermal Insulation of Roofing & Cladding of Buildings and for construction of cold rooms.

Lloyd PUF / PIR panel System comprises of Pre-Fabricated sandwich panels with CFC & HCFC free Polyurethane foam at a density of 402 kg/cu.m. /Polyisocyanurate foam at a density of 4542 kg/cu.m. as core and with profiled sheeting / plain ribbed sheeting made out of Galvanized / Galvalume Steel as facings on both sides.

Lloyd PUF/PIR Panels come with standard Single / Double Tongue & Groove joint for cold Rooms and Roofing panels and with Concealed Fixing System arrangement for cladding of buildings. Lloyd PUF/PIR Panels are manufactured in the most Modern Continuous Panel making line and can be supplied in lengths up to |2m (Limited due to restriction in transportation). Lloyd PUF/PIR Panels are available in a standard width of Im and in various thicknesses to suit the industry requirements.

Lloyd PIR Roofing, Wall Cladding & Cold Room Panels are FM approved.

PIONEERS IN ROCKWOOL PANELS

Being Pioneer and leaders in the field of Rockwool Insulation, Lloyd Insulations first introduced Lloydroc Rockwool Panels for DG Set Power Projects way back in 1999 and for other industries.

Lloyd Insulations possesses the necessary Infrastructure, Technical and Financial capabilities to execute turnkey orders with Pre-fabricated Rockwool Panels of any magnitude.

LLOYDROC ROCKWOOL PANEL

SYSTEM

Lloydroc Rockwool Panel System Comprises of Pre-Fabricated Composite Sandwich Panels with high density Rockwool converted to Lamellar as core and profiled / plain, colour coated Galvanized Steel / Galvalume Steel Sheet facing on both sides, complete with special joint sealants and fixing ancillaries. Lloydroc Rockwool Panel system provides a one step solution in the form of insulated Walls and Roofings for easy and quicker construction of Turbine - Generator Buildings, DG Set Power Plant buildings, Driers, Ovens and other Industrial Buildings.

Lloydroc Rockwool Panels come with concealed system arrangement for cladding of Buildings and with Profiled Sheets for Roofing and Cladding Applications. Lloydroc Rockwool Panels come with Plain Sheet with Tongue and Groove joints for construction of Partitions, Hot Rooms,

Dryers,Ovens,etc.,

Lloydroc Rockwool Panels offer considerable mechanical strength due to the sandwich effect and Acoustic Insulation properties besides being totally non combustible